Products

ProductsLocation:Home > Welding Oscillator, 30 Series > 30LE2 Welding Oscillator / Welding Torch Oscillator / Welding Weaver

-

YXAWO-30LE2 Linear Welding Oscillator◆ Brief IntroductionWelding oscillator is to increase the width of the welding seam formed through one time welding, is mainly used for a relatively wide welding seam, for example, V-groove welds, fillet welds. When we weld a relatively wide seam, if the welding torch does not swing, the width of formed seam is relatively narrow. To solve this problem, we need to make the welding torch swing back and forth in the width direction along the seam.

- Welding oscillator consists of two main parts, mechanical swing mechanism (we called slide) and electrical control part (we called controller).

- Welding oscillator produced by our company has a high-quality controller and uses the speed & position double closed-loop DC-Servo control technology, to ensure oscillating accuracy and speed will not be affected by the load changes. Due to the oscillating speed and amplitude can be adjusted at any time, so it is easy to achieve the requirements of different weld width and oscillating speed; greatly reduce the labor intensity of the welder; ensure the welding quality and improve the welding efficiency.

Standard Configuration

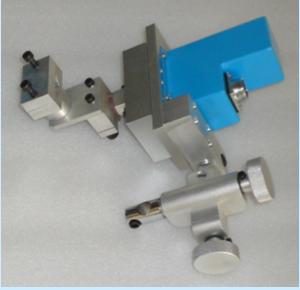

Slide with Options

Panel of Controller

◆ Main Functions and Features

● Oscillating parameters are input by digital knob and displayed in digital, visualized to use.

● With a parameters memory and power-off protection function, ensure the parameters not lost in a sudden

power off.

● With parameters restore memory function, parameters can be automatically recovered to the before

powering status, when the power is on.

● Use the speed & position double closed-loop DC-Servo control technology, to ensure oscillating accuracy

and speed will not be affected by the load changes.

● Motor over-current and over-voltage dual protection function to protect the motor performance and extend

● Motor over-current and over-voltage dual protection function to protect the motor performance and extend

service life.

● Electronic controls oscillating speed, amplitude, left/right dwell, to make operations simple and convenient.

● While oscillator stopping, return to the center automatically.

● Compact structure and reasonable design are conducive to the use of small space.

● Wide input power supply voltage range is suitable for using around the world.

● Electronic controls oscillating speed, amplitude, left/right dwell, to make operations simple and convenient.

● While oscillator stopping, return to the center automatically.

● Compact structure and reasonable design are conducive to the use of small space.

● Wide input power supply voltage range is suitable for using around the world.

◆ Technical Parameters

|

Oscillating Parameters Input Mode |

Digital, Knob Adjustment, LED display |

|

Rated Load |

5Kg |

|

Slide Stroke |

30mm |

|

Maximum Oscillating Speed |

4000mm/min |

|

Maximum Oscillating Frequency |

120times/min |

|

Oscillating Amplitude |

2-25mm |

|

Oscillating Accuracy |

±0.5mm |

|

Left / Right Dwell Time |

0-3s |

|

The Welding Methods to Be Applied |

TIG, MIG, MAG, Plasma Welding |

|

Control Methods |

Speed & Position Double Closed-Loop DC-Servo Control |

|

Slide Structure |

Motor + Guide + Sensor |

|

Input Power Supply |

AC100-240V Single-phase, 50/60Hz, 2A |

|

Outline Dimension |

Controller 240×160×120mm, Slide 135×65×171mm |

|

Mounting Hole Size |

Controller 170 × 120mm ,4-M4; Slide35×18mm, 4-M5 |

|

Weight |

Controller 2.65Kg, Slide 1.3Kg |

|

Standard Configuration |

Controller, Slide, Connecting Cables (including Power Cable and Slide Cable). |

|

User Options |

Welding Torch Holder, Cross Regulation Slide |

In addition, our company can also supply special welding oscillator in accordance with the needs of users.