Products

YXAWST-CE Series Tactile Welding Seam Tracker

◆ Brief Introduction

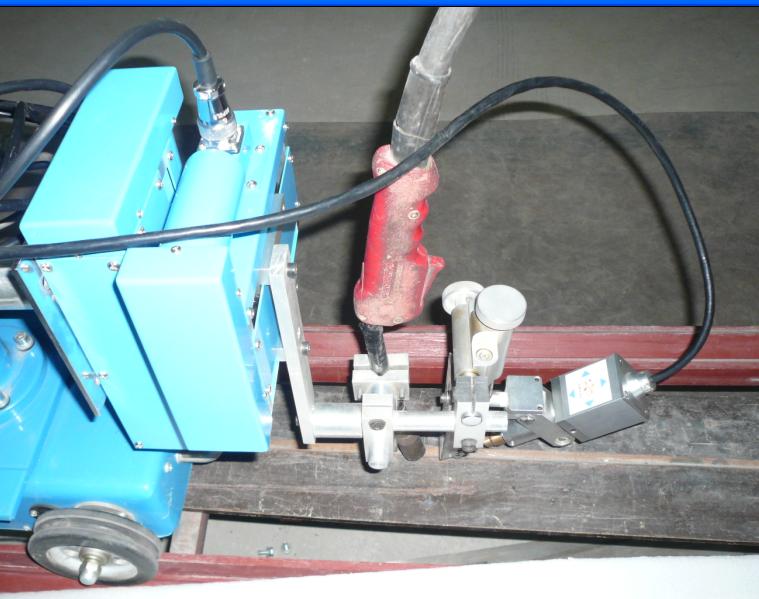

YXAWST-CE Series tactile seam tracking systems deliver precise automated weld joint tracking for submerged arc and GMAW arc welding processes. Ideal for repetitive welding applications, these systems are recommended over manual and semiautomatic welding to improve quality and consistency while reducing operational costs.This kind welding seam tracker can effectively solve the problems brought about by the weld seam deviation; improve the welding quality and welding efficiency; reduce the welding defects generation; greatly reduce the labor intensity of the welder. It consists of Controller, Sensor, Sensor Cross Regulator, Horizontal Slide, Vertical Slide and Connecting Cables. This system uses high-precision sensor to detect groove shape changes’ signals of the workpiece. Then, send the signals to sontroller. Controller drives the horizontal slide and vertical slide to control welding torch move quickly and accurately, and thus achieves auto welding tracking. It has been supplied on many kinds of auto welding equipments, for example welding manipulator, gantry welding machine, cantilever welding machine, elbow welding machine, vertical / girth welder, the flange welding machine, submerged arc / gas shielded welding carriage, etc.

Standard Configuration

Panel of Controller

Application

◆ Main Functions and Features

● Response time control can identify and filter the obstacles (for example: welding spatter) not need adjusting.

● The left/right direction switching function makes easy to install and change the welding direction.

● Several ways to enter into the welding seam.

● Positioning welding detection.(Options)

● Welding seam end detection.(Options)

● Remote Control Interface (Options)● Output Interface used to connect with the auto welding equipment, makes the centralized control

easily. (Options)

◆ Technical Parameters

|

Model Technical Data |

YXAWST-608CE |

YXAWST-100CE |

YXAWST-1050CE |

YXAWST-200CE |

|

Maximum Load |

8Kg |

25Kg |

50Kg |

100Kg |

|

Slide Stroke |

60mm |

100mm |

100mm |

200mm |

|

Maximum Slide Speed |

200mm/min |

450mm/min |

300mm/min |

350mm/min |

|

Tracking Accuracy |

±0.25mm |

±0.3mm | ||

|

The Welding Methods to Be Applied |

TIG, MIG, MAG, Plasma Welding |

Single-wire SAW |

Two-wire SAW | |

|

Slide Structure |

Motor + Guide + Screw | |||

|

Controller |

Program Control | |||

|

Input Power Supply |

AC100-240V Single-phase, 50/60Hz, 2A | |||

|

Standard Configuration |

Controller, Vertical Slide, Horizontal Slide, Sensor, Sensor Cross Regulator,

Connecting Cables (No Options Functions) | |||

|

User Options |

Remote Control Interface, Output Interface, Remote Control Box ( Including the Connection Cables), Probes to adapt to various Welding Groove-Shaped, Positioning Welding Detection, Welding End Detection. | |||

In addition, our company can also supply special Welding Seam Tracker in accordance with the needs of users.